Semi-trucks are the backbone of the logistics industry, making their reliable performance absolutely critical. To keep your semi-truck running at peak efficiency and minimize unexpected breakdowns, a proactive and comprehensive maintenance plan is key. Here’s a step-by-step guide designed to help semi-truck owners keep their rigs in top condition:

1. The Daily Walkaround Inspection:

Before each trip, a thorough walkaround inspection is your first line of defense. Check for:

- Leaks: Look for any signs of fluid leaks under the engine, transmission, and other components.

- Tire Condition: Inspect tires for proper inflation, uneven wear, cuts, or bulges.

- Lights: Test headlights, taillights, brake lights, and turn signals for proper function.

- Mirrors and Windows: Ensure mirrors are clean and properly adjusted. Check for any cracks or damage to windows.

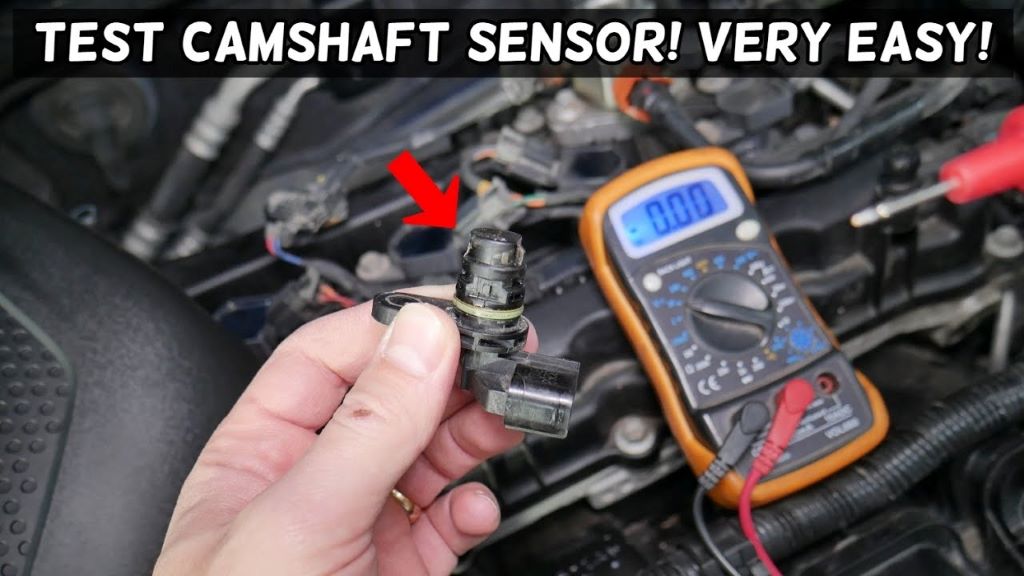

- Connections: Make sure hoses, wires, and belts are securely connected and not showing signs of wear. Additionally, it’s important to check all parts of your vehicle, including understanding what is a wheel seal on semi trucks, to ensure everything is in optimal condition.

2. Weekly Checks:

- Engine Fluids: Check and top off engine oil, coolant, and washer fluid levels.

- Brake System: Inspect brake pads for wear and ensure there are no leaks in the brake lines.

- Air Filter: Check the air filter for dirt and debris; replace if necessary.

- Cab Interior: Clean the interior of the cab, including windows, dashboard, and seats.

3. Monthly Maintenance:

- Battery: Check battery terminals for corrosion and clean them if needed. Test the battery’s charge.

- Wheel Bearings: Inspect wheel bearings for proper lubrication and signs of wear.

- Chassis Lubrication: Lubricate all grease fittings on the chassis and suspension.

- Trailer Inspection: Check trailer lights, brakes, and tire condition.

4. Quarterly Maintenance:

- Engine Oil and Filter Change: Replace the engine oil and oil filter as per the manufacturer’s recommendations.

- Fuel Filter: Replace the fuel filter to prevent contaminants from affecting engine performance.

- Transmission Fluid: Check transmission fluid level and condition; top up or replace if needed.

- Coolant System: Inspect hoses and clamps for wear; pressure test the cooling system for leaks.

- Differential Fluid: Check differential fluid level and change if necessary.

5. Semi-Annual Maintenance:

- Drive Belts: Inspect and replace any worn or frayed drive belts.

- Brake System: Check brake lining thickness and replace if needed. Inspect brake drums and rotors.

- Steering System: Check the power steering fluid level and look for leaks. Inspect the steering linkage for wear.

- Suspension: Inspect shock absorbers and springs for leaks and damage.

- Electrical System: Check wiring for damage, and inspect connections for corrosion.

Related: How to Take Care of a Semi Truck

6. Annual Maintenance:

- Engine Tune-Up: If needed, adjust valves, check timing, and replace spark plugs (for gasoline engines).

- Transmission Service: Have the transmission serviced by a qualified technician.

- Clutch Adjustment: (For manual transmissions) Check and adjust the clutch as needed.

- Alternator and Starter: Have these components tested and replaced if necessary.

7. Record Keeping:

Maintain a detailed maintenance logbook to track all repairs, replacements, and inspections. This log will prove invaluable for warranty claims, resale value, and overall fleet management.

Additional Tips:

- Pre-Trip Inspection: Develop a comprehensive checklist for your daily walkaround inspection.

- Use Quality Parts: Always use high-quality parts and fluids that meet or exceed the manufacturer’s specifications.

- Professional Service: For complex repairs or services, rely on qualified and experienced technicians.

- Cleanliness: Keep your semi-truck clean, both inside and out. This helps prevent corrosion and makes it easier to spot potential issues.

By following this step-by-step maintenance plan and incorporating these additional tips, you can significantly extend the life of your semi-truck, improve fuel efficiency, reduce downtime, and ensure safe and reliable operation on the road. Remember, proactive maintenance is always more cost-effective than unexpected repairs.