Pressure-treated wood is widespread for outdoor projects like decks, fences, retaining walls, and furniture. The pressure treatment process forces chemical preservatives deep into the wood, protecting it from rot, fungi, insects, and other sources of decay. But how to tell if wood is pressure treated? There are some clear signs to look for.

Why Use Pressure Treated Wood?

Before discussing the identification details, it’s helpful to understand why pressure-treated wood is so popular.

When wood is exposed to moisture and the elements, it is susceptible to:

- Rotting

- Mold growth

- Insect infestation

- Fungal decay

- General deterioration

This damage can quickly ruin wood, causing safety issues, aesthetics problems, and the need for frequent replacement.

Pressure treatment applies chemical preservatives to the wood under high pressure. This forces the protective chemicals deep into the cellular structure of the wood instead of just coating the surface.

Common types of pressure treatment include:

- Chromated copper arsenate (CCA) – a mix of chromium, copper, and arsenic

- Alkaline copper quaternary (ACQ) – a copper-based preservative

- Copper azole (CA) – uses copper as the leading fungicide

These chemicals preserve the wood by killing microorganisms and insects that can destroy it. They also act as a shield to protect the wood cell walls.

The result is wood that can withstand decades of exposure to moisture, rain, snow, sun, bugs, and fungi without rotting or deteriorating.

Let’s review the telltale signs that wood has undergone pressure treatment.

Check for Stamps or Branding

The easiest way to identify pressure-treated wood is to check for stamps or branding that label it as such.

Stamps are often applied directly to the wood by the treatment company or supplier before shipping. Branding can also be printed right onto the wood by the manufacturer.

Here’s what to look for on the stamps/branding:

- The words “Pressure Treated” or “Pressure Treated Wood.”

- Abbreviations like “PT” or “PTW”

- A statement that the wood meets specific standards like “AWPA U1” or “Meets CCA-060 Standards.”

- A mark indicating the preservative used, like “ACQ Treated” or “CA Treated.”

- The name, logo, or initials of a significant treatment company like “Osmose” or “KS.”

If you see any stamps or branding like that, you can be confident the wood has been pressure-treated.

Look for Color Differences

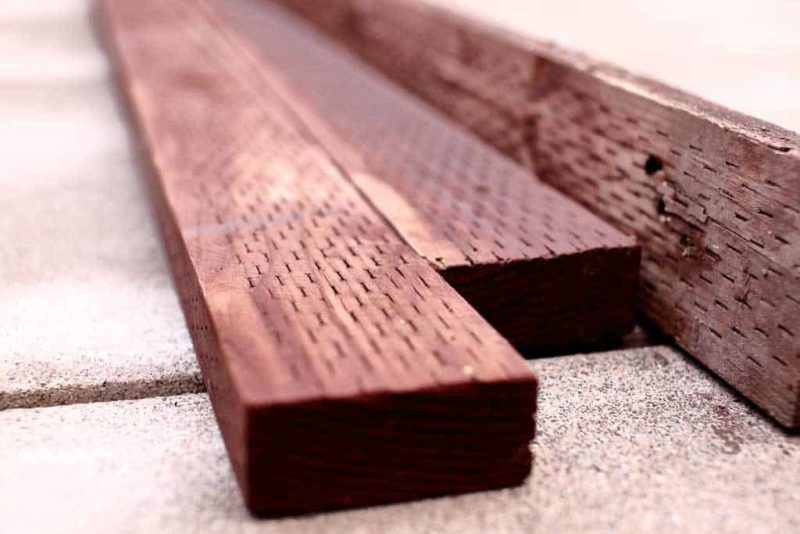

The chemicals used in pressure treatment tend to impart a greenish or brownish hue to the wood. The color change depends on factors like wood species, chemicals used, and the time since treatment.

Here are some color differences to look for:

- A distinct green tint, especially on lighter woods like pine. This green comes from the copper in treatments like CCA, ACQ, and CA.

- A darker brown color than untreated wood. This can be subtle, but you may notice a more prosperous, chocolatey brown.

- Dark blackish spots or streaks. This effect is most pronounced around the ends and cut edges.

- A weathered grey look. Over time, exposed treated wood will turn greyish as the chemicals wash out.

If you see these telltale signs of color change, it’s a good bet the wood has been treated.

Look Closely at the End of Grain

A great place to check for pressure treatment is on the end grain of a cut piece of dimensional lumber.

The end grain is like a road map showing the internal cellular structure of the wood. When you closely examine the end of a treated board, you can often clearly see the chemicals penetrated deep into the wood cells.

Signs to look for on the end grain:

- A greenish or brownish tint permeates well into the wood, not just on the surface.

- Dark spots or streaks of color concentrated around the outer growth rings.

- No signs of mold, stains, insects, or other decay.

Conversely, when you inspect the end grain, untreated wood will look lighter and more natural on the inside.

So, look closely at that cross-section to help tell whether treatment chemicals are present.

Detect an Oily or Waxy Feel

Many pressure treatment chemicals leave wood feeling slightly oily or waxy to the touch. This is due to the preservatives’ water-repellent properties.

Run your hand over the wood grain and pay attention to the texture. See if treated boards feel:

- Slightly oily or resinous

- Waxy, like they have a thin coating

- Not as dry and porous as untreated wood

This is a subtle difference you pick up over time with experience. But it can serve as another clue to spot pressure-treated wood by feel.

Check for Instruction Labels

Retailers are required to attach labels marking lumber as pressure-treated. Look for small plastic or metal tags stapled or tied to boards with language like:

- “Pressure Treated”

- “Do Not Burn”

- “Do Not Inhale Dust”

- “Wear Gloves and Mask When Machining”

- Warnings about disposal

These safety labels confirm the wood has gone through chemical treatment. They aim to inform consumers of proper handling, usage, and disposal guidelines.

Weigh the Wood

Pressure-treated lumber tends to be heavier than untreated planks. The dense preservative chemicals increase the overall weight.

A rough guide:

- Treated lumber weighs about 10% more than untreated wood.

- A common 2x6x8′ treated board weighs around 20 lbs.

- Treated 5/4 decking boards feel noticeably heavy.

Weigh the wood in your hands. Compare similar-sized treated and untreated planks. If the wood feels considerably heavier for its size, it’s likely treated.

Know Where to Expect Treatment

Pressure treatment is mainly used for dimensional softwood lumber. This includes boards for outdoor projects like:

- Decks

- Fences

- Landscape edging

- Retaining walls

- Picnic tables

- Porch trim

- Sill plates

So, if you’re using this type of exterior construction lumber, expect that it’s treated.

Conversely, hardwood boards, interior plywood, and finishing lumber are rarely treated. The chemicals can interfere with finishing and indoor air quality.

Knowing the expected usage for the wood species can serve as a clue about whether it’s treated.

Use a Field Testing Kit

You can use a field testing kit to detect treatment chemicals for definitive confirmation. When exposed to preservative compounds like arsenic and chromium, these kits use simple color-change reactions.

Field test kits are inexpensive and available at home centers and hardware stores. To use them, clip a small wood sample, apply the chemicals, and check for a color change.

While not always necessary, test kits confirm whether modern treatment chemicals exist.

When in Doubt, Ask

If you can’t tell whether the wood has been treated, ask the lumber provider or person you purchased it from.

Big box stores, pro suppliers, sawmills, and woodworkers should know the treatment status of their inventory. Don’t hesitate to ask.

It takes some know-how to identify treated wood by sight and feel alone. When uncertain, go straight to the source for a definitive answer.

Signs of Untreated Wood

To recap, here are some clear indicators that dimensional lumber or timber has NOT been pressure-treated:

- No stamps or branding with treatment standards present

- A natural light wood color instead of greenish or brownish hues

- No dark streaks or coloration on the end grain

- A dry, porous feel rather than oily/waxy

- No instruction labels stapled or attached

- It weighs noticeably less than treated planks

- Being used for interior rather than exterior applications

Wood with these signs has almost certainly not undergone chemical preservation. When used outside, it’s at high risk for rot and insect damage.

Why Does it Matter?

Now that you know how to tell if wood is treated, you may wonder why it matters in the first place.

There are a few important reasons you need to be able to identify pressure-treated lumber:

Safety

Some older treatment chemicals contain compounds like arsenic and chromium that are hazardous in high concentrations. Always take precautions by:

- Wearing gloves and a mask when machining treated wood

- Washing exposed skin after handling

- Controlling construction dust

- Disposing of treated wood properly

Avoid burning treated wood, as the smoke can release the chemicals. Knowing which boards have been treated allows you to prioritize safety.

Preventing Early Failure

Using untreated wood in outdoor projects can lead to early rotting, cracking, insect damage, and fungal decay. This results in aesthetic problems, weak structural integrity, and the need for frequent replacement.

Knowing which wood has been treated versus untreated means, you can select the appropriate material for the job. Use untreated lumber only for indoor applications or outdoor projects that won’t be exposed to the elements. Choose treated lumber for any wood structure that gets wet or has prolonged exposure to weather.

This prevents premature project failure and safety issues down the road.

Knowing When Treatment is Needed

Some wood projects require the protection of pressure treatment, while others don’t. Manufacturers treat dimensional construction lumber because it’s designed for outdoor use where treatment is needed.

On the other hand, fencing, siding, decking, and landscaping boards also come in “above-ground” varieties that resist decay without complete pressure treatment.

Identifying treated wood helps determine if the extra chemical preservation was warranted based on the project plans. Getting clarification from retailers or reading labels can prevent unnecessary treatment.

Proper Fasteners and Hardware

The chemicals used in pressure-treated wood can quickly corrode regular steel fasteners and hardware. Using the wrong nails, screws, hangers, connectors, and more can compromise the structural integrity of the build.

Knowing which lumber has been treated allows the selection of compatible stainless steel or exterior-rated hardware that will withstand the chemicals without corroding.

Special Handling on Fine Projects

Some woodworkers intentionally avoid using treated wood on special indoor projects, custom furniture, cabinetry, and finishing pieces. The chemicals and color changes may interfere with certain glues, stains, and finishes.

Identifying treated boards means setting them aside for outdoor use only. Save untreated wood for exemplary woodworking projects where chemicals could cause issues.

There are many good reasons for accurately determining whether wood has been pressure-treated. Taking the time to check carefully will improve the safety, longevity, structural security, and aesthetics of your woodworking projects.

Conclusion

Identifying pressure-treated wood requires some upfront knowledge, but a few clear techniques, such as checking stamps, color, weight, end grain, and project type, make it reasonably easy to figure out.

Determining if the wood has been treated accurately pays dividends through improved safety, material selection, project longevity, and reduced replacements.

Knowing what to look for helps ensure you use suitable wood for interior and exterior applications. So, scrutinize lumber and apply the tests in this guide before starting major wood projects. Carefully sourcing and selecting treated and untreated wood is a critical first step in successful woodworking.

FAQs

Q: Can pressure-treated wood be stained or painted?

A: After the treated wood has dried, you can apply stains and paints. The chemicals won’t interfere with most coatings. However, you may need to use a wood conditioner first for better absorption.

Q: Does treated wood last forever outside?

A: No material lasts forever. However, when used in suitable outdoor applications, adequately treated wood can last decades without significant rot or insect damage.

Q: Can you use treated wood in ground contact?

A: Ground contact-rated treated wood can be buried in the soil. But untreated wood will quickly rot underground. Always use the proper grade of treatment.

Q: Is treated wood safe for raised vegetable gardens?

A: It depends on the exact treatment chemicals used, which vary by manufacturer. Some types, like CCA, are not recommended for garden beds. Check branding or ask suppliers to confirm which wood is rated for garden use.

Q: Why is treated wood still wet when purchased?

A: The treatment process uses water-based solutions. Freshly treated wood retains moisture until it completes a drying process, which can take several weeks. The humidity helps chemicals soak deeply into the wood cells.